Rotary drum dryer

LCDRI Rotary Drum Dryer is also known as Drum Drying Equipment or Rotary Dryer is a dryer equipment used in mining equipment.

The most common and widely suitable for dry and non gold metal drum dryer is mine, heavy, floating magnetic concentrate and cement industry and the coal industry of coal mud clay etc.. It is characterized by high productivity, easy to operate.

LCDRI Drum Dryer Cylinder is a horizontal rotating cylinder, the internal front to back welding have all kinds of copy boards staggered from different angles, in different types of refractory brick kiln according to the requirements set at the feed end to prevent dumping a door ring and a spiral copy board. Has the advantages of reasonable structure, excellent workmanship, high yield, low energy consumption, easy operation.

Process description

LCDRI Rotary Drum Dryer is also known as Drum Drying Equipment or Rotary Dryer is a dryer equipment used in mining equipment.

The most common and widely suitable for dry and non gold metal drum dryer is mine, heavy, floating magnetic concentrate and cement industry and the coal industry of coal mud clay etc.. It is characterized by high productivity, easy to operate.

LCDRI Drum Dryer Cylinder is a horizontal rotating cylinder, the internal front to back welding have all kinds of copy boards staggered from different angles, in different types of refractory brick kiln according to the requirements set at the feed end to prevent dumping a door ring and a spiral copy board. Has the advantages of reasonable structure, excellent workmanship, high yield, low energy consumption, easy operation.

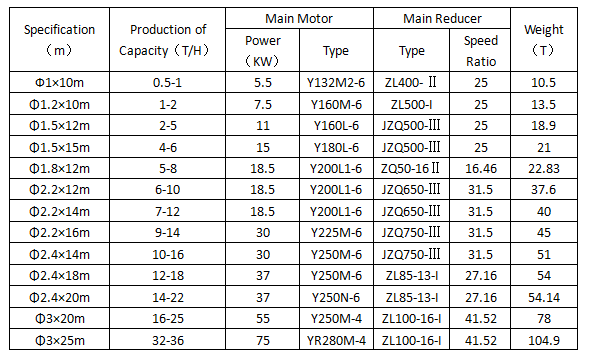

Specifications

LCDRI have the standard types of Rotary Drum Dryer as below chart.

LCDRI also could design and manufacture the Rotary Drum Dryer according to customers’ concrete specifications.

Features

By drying machine combined lifting device of LCDRI design and production system for technological innovation in many aspects in the feed, the new combined lifting device is adopted, to overcome the traditional drying machine “wind tunnel” phenomenon, high thermal efficiency, reduce coal consumption of about 20%.

The use of a variety of combustion furnace: high temperature boiling furnace, pulverized coal and pulverized coal stove.

The transmission size of the gear “Pin Pin”can be used to replace the gear, replacing the traditional cast steel gear, cost savings, but also greatly reduce maintenance costs and time.

Centralized Control System can be used to realize the monitoring and management of large enterprises.

Production capacity is bigger, which can be operated continuously.

Simple structure, easy to operate.

Less trouble, low maintenance costs;

A wide range of applications, it can be used to dry granular materials, for those with large material is also very favorable. With flexible operation, the product allows the production of a larger range of fluctuations, does not affect the quality of the product.

Easy to clean

Projects

LCDRI manufacturing the Rotary Drum Dryer successfully put into production all over the world.