Biomass gasification power generation plant

Introduction of biomass gasification power generation

LCDRI biomass gasification power generation plant uses LCDRI Biomass Carbonization Furnace to burn biomass for producing biogas that drives a generator to make electricity. Furthermore, the extracted or spent steam from the power plant is also used for manufacturing processes or to heat buildings. These combined heat and power (CHP) systems greatly increase overall energy efficiency to approximately 95%.

Main Components

A Biomass Gasification Power Generation Plant is made up of several Main components.

- Biomass Pelletizing System

- Gasification System

- Cooling and Purifying System

- Power Generation System

- Instrument Control System

The annual operating time of the plant is 8000 hours. The Biomass Gasification Power Generation Plant adopts a modular design. All the systems are respectively installed in the 40GP container. The gas purification treatment device is arranged on the upper part of the container. The transportation is convenient, the land occupation is small, the adaptability is strong, and it is not affected by urban planning.

CONTACT US

Key technologies for biomass gasification power generation

Biomass gasification means incomplete combustion of biomass resulting in production of combustible gases, including Carbon monoxide (CO), Hydrogen (H2), Methane (CH4), CmHn, this mixture is called pyrolysis gas that can be used to run internal combustion engines, and generate CHP. The production of pyrolysis gas called gasification, is partial combustion of biomass (such as rice husk, woodchips, saw dust, crop stalk, coconut hull, bagasse, olive pomace etc.). The reactor is called Biomas Carbonization Furnace. LCDRI Biomass Carbonization Furnace is the ideal machine for turnning the agricultural wastes to the useful energy. LCDRI has advanced production techniques and introduced foreign technologies to design professional Biomass Carbonization Furnace. Our professional furnace accepts wide-ranged raw materials, almost all the biomass wastes can be carbonized, such as wood, wood chips, coconut shells, straws,sawdust, rice husk, fruit peel, etc. Through the process of carbonization, biomass wastes could turn into charcoals, electricity and biogas under high-temperature environment.

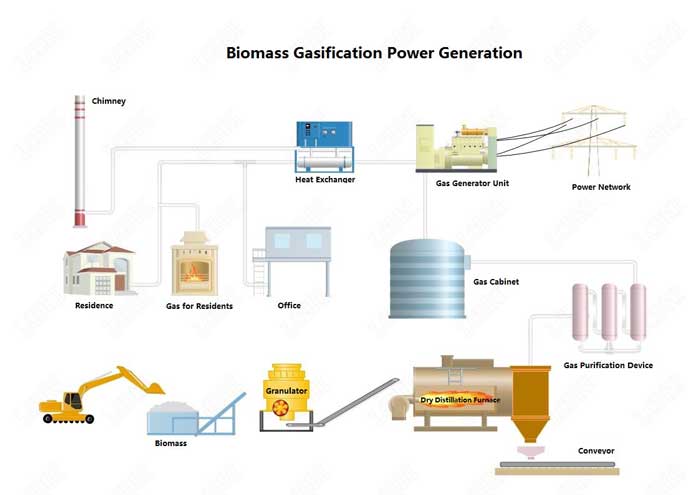

Process Flow of Biomass Gasification Power Generation Plant

Biomass carbonization process flow including

Biomass Pretreatment (Pulverization, Drying, Granulation) — Biomass Absolute Oxygen Distillation — Flue Gas Treatment (Collection, Filtering, Cooling, Storage) and Combustion Utilization — Charcoal (Slag) Collection and Storage.

1. Biomass Pretreatment

First of all, the collected biomass will be pulverized, dried in a dryer, pressed, and made into a certain size of particulate materials.

2. Biomass absolute oxygen distillation

The granular biomass is transported to the Biomass Carbonization Furnace through the conveying device, and the gas and the remaining biomass carbon (residue) are decomposed by heating the granular biomass in the Biomass Carbonization Furnace. The combustible gases and water vapor are collected, filtered, cooled, converted into liquid and separated by collecting pipes. The combustible gases are transported to the gas tank and then used as fuel for combustion power generation or for heating the Biomass Carbonization Furnace.

3. Flue gas treatment and combustion utilization

After carbonization process, the generated flue gas mixed with vapour and flammable gas, through dedust unit and filter unit, make it clean, and then send to cooling unit, water and tar will be separated and collected from flue gas. Noncondensing flammable gas will be conveyed to the gas holder, after enter into combustion system for burning, it could be used for heating, electricity generation, heat supply, hot water supply and etc.

4. Charcoal (Slag) Collection and Storage

Below the gas collection hood, adopt rotary air lock valve, charcoal (residual slag) will be transported to conveying machine, and then store in the tank for final packing.

Characteristics of LCDRI Biomass Gasification Power Generation Plant

1. Noise emissions

The system noise mainly comes from the generator set. The generator set is a container-type design. The unit box is lined with sound-absorbing cotton and sound-absorbing panels, and the noise reduction of the external body is 1m to 75dB. The garbage sorting workshop and the gasification power generation equipment workshop are separately set up with separate workshops. The plant is equipped with noise reduction measures, and the field boundary noise is less than 55dB.

2. Atmospheric emissions

The gas and water are purified by the system to produce clean gas and medium water. The entire production process has no exhaust gas and no odor. The flue gas produced by the clean gas after combustion by the generator set, the main pollutant content index: NOx≤20mg/Nm3; SO2≤5mg/Nm3; particulate matter≤5mg/m3.

3. Water discharge

The water in the domestic garbage is first heated to 500-800°C superheated steam by the gasification system, and then becomes condensed water. There is no bacterial problem in the water. The chemical method is used to clean water, and the water can be used as circulating cooling water and greening water.

4. Solid Waste

The system processes the organic matter in domestic waste, and the reduction can reach more than 99%. The solid emissions components are mainly harmless and non-polluting inorganic materials that can be directly landfilled or used as industrial raw materials for building materials.

Plant Case

Fuel gas type Indirect heating biomass electricity generation gasification unit for Finland client in year 2012