Suspension calcination calcium aluminate cement production line plant

Introduction

Our institute developed a new Suspension Calcination Technology for calcium aluminate production, and its characteristics:

- High quality, energy saving effect is remarkable: products comply with the Chinese Standard GB, preheater outlet temperature 320 ~ 330℃, the standard coal consumption below 150KG/T.

- The production scale is large and the degree of automation is high: the single line production can reach 600 thousand TPY, and the whole plant realizes the central control operation and control.

- Production line investment for an annual output of 300 thousand tons of calcium aluminate production line, total investment estimate RMB90~98 million.

The product (calcium aluminate) is widely used in refractory material industry, except from the raw material of polyaluminium chloride production.

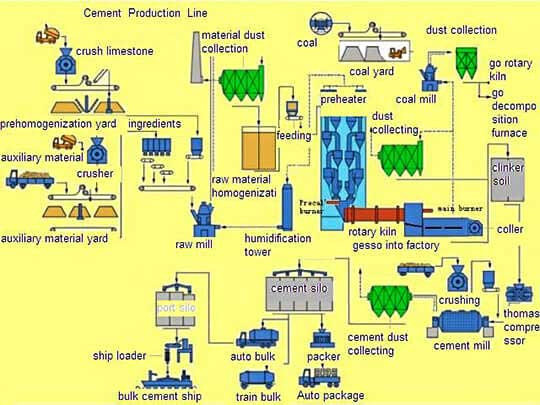

Cement production line flow chart

Cement calcination process

1. Crushing and Preblending

Limestone, clay, iron ore, coal, etc. Limestone is the largest amount of raw materials in cement production. After mining, the size of limestone is large with high hardness, so the limestone crushing plays a more important role in cement plant.

2. Raw Material Preparation

In the cement production line, producing 1 ton cement need grind at least 3 tons materials (including raw materials, fuel, clinker, mixed materials, gypsum). Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%. So choosing the right grinding mills in cement plant is very important. LCDRI can provide cement vertical mill. LCDRI cement vertical roller mill in the production of cement specific surface area up to 3800 cm²/ g with stable and reliable quality. It can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional ball mill, and the power saving effect is very remarkable.

3. Raw Materials Homogenization

Adopting the technology of homogenization could rationally get the best homo-effect and afford an eligible production to the demand.

4. Preheating and Precalcing

Preheater and calciner are key equipment for precalcing production technique.

5. Burning Cement Clinker in a Rotary Kiln

The calcination of rotary kiln is a key step of cement plant, which makes directly influence on the quality of cement clinker.

6. Cement Grinding

Grinding cement clinker (and gelling agent, performance tuning materials, etc) is used to grind the cement to the appropriate size (in fineness, specific surface area, etc.), optimize cement grain grading, increase the hydration area and accelerate the hydration rate to meet the requirements of cement paste setting and hardening.

Parameter

|

Specification |

Dimension |

Capacity(t/h) |

Speed of revolution(r/min) |

Power of motor(kw) |

Weigh(t) |

||

|

Diameter(mm) |

Length(mm) |

Inclination(mm) |

|||||

|

Φ2.0*40 |

2 |

40 |

3 |

2.5-4 |

0.23-2.26 |

37 |

119.1 |

|

Φ2.2*45 |

2.2 |

45 |

3.5 |

3.4-5.4 |

0.21-2.44 |

45 |

128.3 |

|

Φ2.5*50 |

2.5 |

50 |

3 |

6.25-7.4 |

0.62-1.86 |

55 |

187.4 |

|

Φ2.5*54 |

2.5 |

54 |

3.5 |

6.9-8.5 |

0.48-1.45 |

55 |

196.3 |

|

Φ2.7*42 |

2.7 |

42 |

3.5 |

10.0-11.0 |

0.10-1.52 |

55 |

198.5 |

|

Φ2.8*44 |

2.8 |

44 |

3.5 |

12.5-13.5 |

0.437-2.18 |

55 |

201.3 |

|

Φ3.0*45 |

3 |

45 |

3.5 |

12.8-14.5 |

0.5-2.47 |

75 |

210.9 |

|

Φ3.0*48 |

3 |

48 |

3.5 |

25.6-29.3 |

0.6-3.48 |

100 |

237 |

|

Φ3.0*60 |

3 |

60 |

3.5 |

12.3-14.1 |

0.3-2 |

100 |

310 |

|

Φ3.2*50 |

3.2 |

50 |

4 |

40.5-42 |

0.6-3 |

125 |

278 |