First, What is sludge pyrolysis retorting gasification?

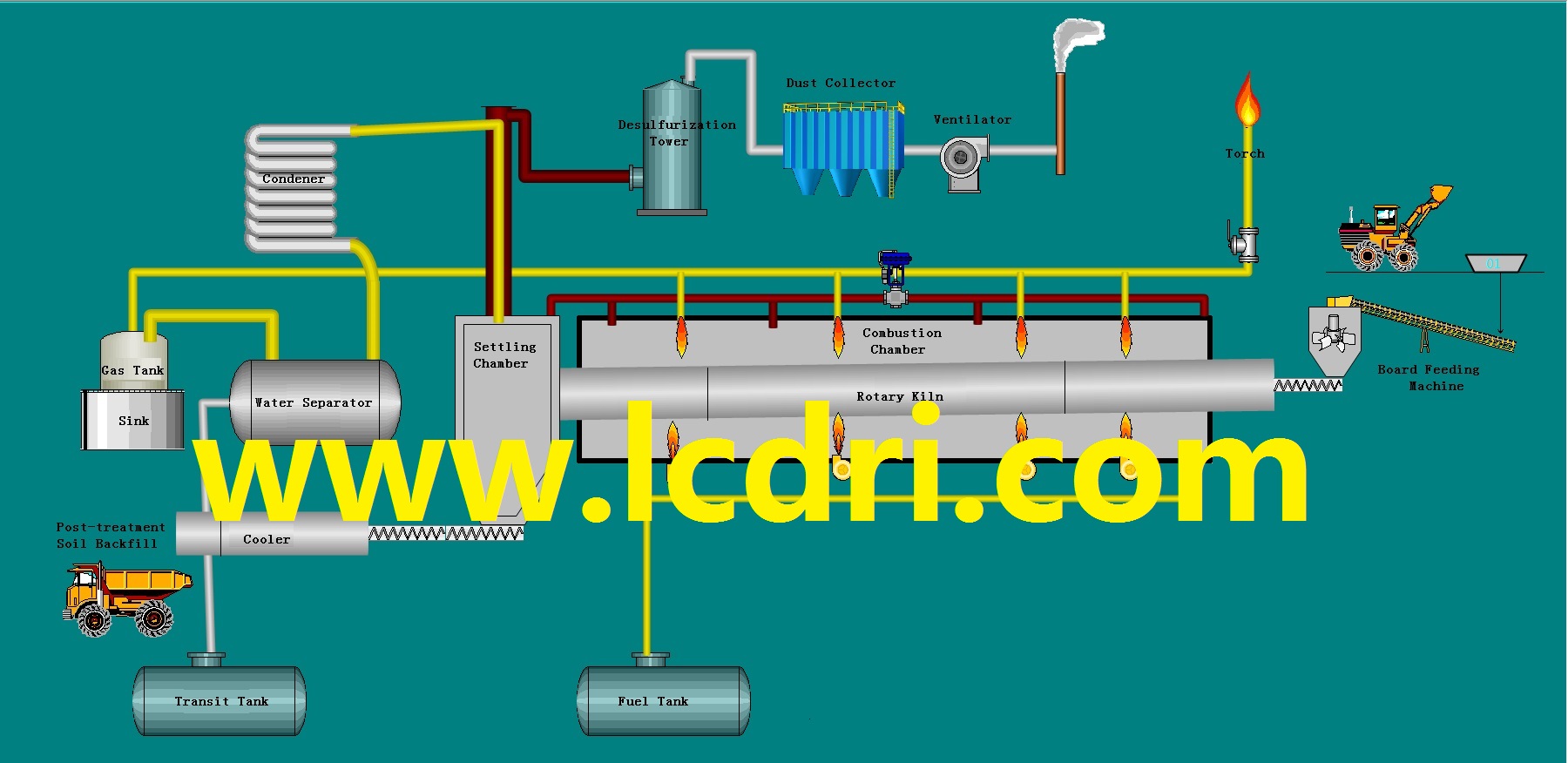

Sludge pyrolysis retorting gasification is to use a composite heating mode to heat the sludge to 150 ° C ~ 600 ° C, the organic matter and water are separated from the solid phase and converted into gas phase; then enter the filter device to filter out the dust in the hydrocarbon vapor. The clean hydrocarbon vapor is introduced into the condensing and separating system, and the water, oil and dry gas are separated in different temperature ranges, and respectively enter the gas cabinet, the oil tank and the water tank. The exhausted tail passes through the dust collecting and purifying system to purify the exhaust gas. , to meet emission standards.

Second, The six core systems of sludge pyrolysis retorting gasification

The six core systems for sludge pyrolysis retorting gasification include: pretreatment system, pyrolysis retorting gasification system, condensing separation system, flue gas purification system, waste heat utilization system and automatic control system.

1. Pretreatment system

The pretreatment system is: pretreatment for crushing the sludge;

2. Pyrolysis retorting gasification system

The pyrolysis retorting gasification system is: after heating the sludge to 150°C to 600°C in a composite heating mode, the organic matter and water are converted into a gas phase, separated from the solid phase, and then enters a filtering device to filter the dust in the hydrocarbon vapor. To allow clean hydrocarbon vapors to enter the condensing separation system;

3. Condensation separation system

The condensing separation system is: hydrocarbon vapor enters the condensing system, and separates water, oil and dry gas in different temperature ranges, and enters the gas cabinet, the oil tank and the water tank respectively;

4. Flue gas purification system

The flue gas purification system is: purifying the exhaust gas after the combustion through the dust collecting and purifying system to meet the discharge standard;

5. Waste heat utilization

The waste heat utilization is: the high-temperature exhaust gas discharged from the system converts the heat energy through the waste heat boiler and the heat exchanger, and can provide the purposes of power generation, heat supply and cooling;

6. Automatic control system

The automatic control system is: using advanced computer distributed control system (DCS system) to realize automatic control and remote monitoring of all parameters of the system.

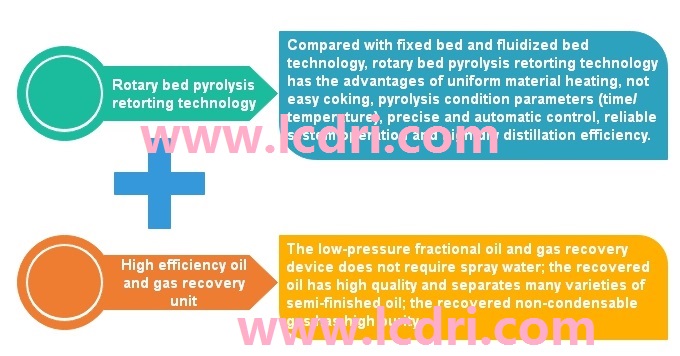

Third, The core technology of sludge pyrolysis retorting gasification

Fourth, The innovation of sludge pyrolysis retorting gasification

1. Modular design: easy to transport and quick installation, can be configured according to project needs;

2. Wide range of applications: it can handle all kinds of oily wastes, and can also be used for soil remediation and other chemical solid waste hazardous waste treatment;

3. Continuity: The system can operate continuously for 8000 hours/year;

4. The solid content of the system processed is less than 0.3%, meeting the most demanding environmental requirements;

5. Unique inlet and discharge design to meet the continuous operation of high viscosity materials;

6. Advanced automatic intelligent control system enables the equipment to operate safely and efficiently;

7. High-temperature pyrolysis retorting and indirect heating of materials. Compared with incineration technology, no harmful gas emissions are generated, and the entire system can meet the most demanding emission requirements.

Entrusted by a department in May 2014, Luoyang Building Material and Architectural Design and Research Institute carried out research and development of comprehensive utilization of oil sands in Buton Island, Indonesia. In June 2015, completed the development and construction of a 100,000 tons/year oil sands dry distillation pilot line, and successfully produced Out of the first barrel of high quality shale oil. In July 2016, the annual production line of 400,000 tons of oil sludge sand was started, and it was put into operation in June 2018.