Domestic garbage gasification is the dream of garbage disposal industry. Compared with traditional garbage incineration, garbage gasification has no emissions of ash and dioxins. Compared with the past landfill, it will not occupy land, and will not cause soil and groundwater pollution.

I. Current Status of Domestic Waste Treatment

In terms of waste disposal methods, sanitary landfill, direct incineration and organic compost were the main disposal methods in China before. Landfill was the main disposal method, accounting for 50%, incineration 12%, compost less than 10%, and nearly 30% of domestic waste had not yet been disposed of.

Landfill and incineration have always been traditional ways of garbage disposal, but landfill not only occupies a large amount of taxi land, but also has a negative impact on the ecological environment. A large number of garbage has been stored for a long time, resulting in leachate pollution to the surrounding environment. The dioxin content produced by direct incineration of garbage seriously exceeds China’s environmental protection standards and harms human health. The phenomenon of domestic refuse siege is becoming more and more serious. At present, there is an urgent need for disposal methods suitable for the characteristics and conditions of domestic refuse in China, so as to make the waste harmless, resource-based and reduced, and fundamentally solve the secondary pollution problem of waste disposal.

For a long time, because the large-tonnage (large-scale waste incineration plants over 500 tons/day) waste incineration power generation is the professional field of state-owned enterprises and central enterprises, Luoyang Building Materials Architectural Design and Research Institute has focused on the small and medium-tonnage (less than 350 tons/day) domestic waste treatment market, and spent more than ten years independently developing domestic waste pyrolysis and gasification technology, which has broken the big domestic enterprises. Tonnage domestic waste disposal is an industry problem with large investment and serious secondary pollution. Below we will understand the process and technology of domestic waste pyrolysis and gasification.

II. Overview of Domestic Waste Pyrolysis and Gasification Power Generation Technology

Pyrolysis and gasification technology is called the third generation waste treatment technology, and it is the latest method of waste treatment. Pyrolysis gasification power generation technology adopts unique proprietary technology in furnace body design. “After the garbage is transported to the power plant, it is piled up for 3 to 5 days for further fermentation. After that, the garbage will be sent to the first combustion chamber of the furnace, where it is dried, pyrolyzed and gasified to combustible gases. The temperature of the first combustion chamber is 600-800 degrees Celsius. After that, the combustible gases enter the second combustion chamber and are fully burned here. Organic matter is heated in anaerobic and anoxic conditions to decompose into flammable gases. In the process of pyrolysis and gasification, electricity can also be generated, with an average of 320 kilowatt-hours generated by a ton of garbage, and the residue generated thereafter can be used in the building materials industry. The gases, solids and water produced in the whole process can be treated and recovered, and the discharge after garbage treatment is greatly reduced. “This technology effectively avoids the long-distance transportation of garbage and realizes on-site treatment, which is very suitable for small and medium-sized cities.

III. Pyrolysis and Gasification Process of Domestic Waste

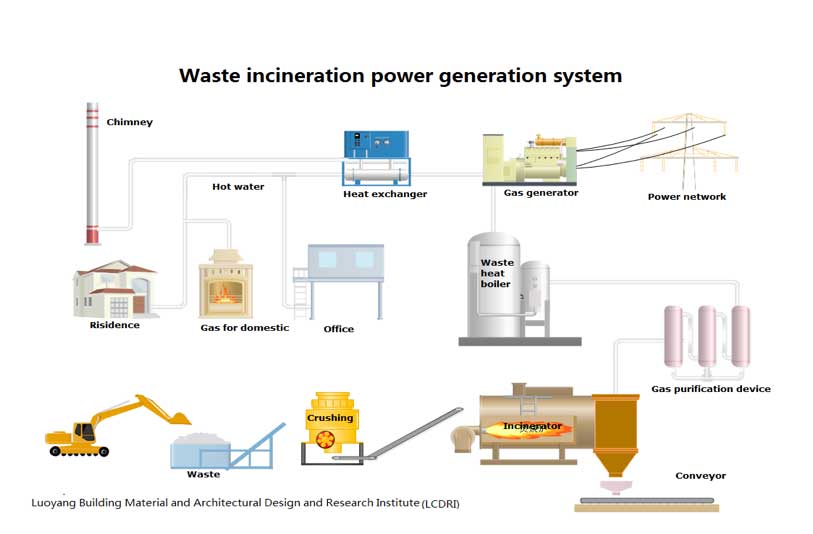

Waste pyrolysis gasification (resource) treatment system mainly includes: receiving and feeding system, pyrolysis gasifier system, waste heat utilization (power generation) system, flue gas purification treatment system, ash collection system, landfill leachate treatment system, automatic control system, etc.

III.Characteristics of rotating pyrolysis and gasification technology for domestic waste

Unlike traditional direct Chu-firing methods (such as grate, rotary kiln, solidified bed, etc.), the basic principle of solid waste pyrolysis and gasification process is to completely treat solid waste and fully recover energy under the condition of no oxygen or lack of oxygen. The fuel-to-flue gas cycle process at high temperature includes the following steps: drying, pyrolysis, gasification and combustion. The first three processes are carried out in the first combustion chamber, while gas combustion occurs in the second combustion chamber. Thermal decomposition is carried out under anaerobic or anoxic reduction conditions. The first combustion chamber is full of quiet combustible gases and always maintains a negative pressure environment in order to prevent the waste from burning directly in the furnace, ensure the inert state of the interior and enable the waste to be fully pyrolyzed. Therefore, compared with the traditional direct incineration of waste, the production of NO, HCL and other harmful substances is greatly reduced, thus the amount of waste gas is also less. The pyrolysis and gasification process of refuse developed by Luoyang Building Materials Architectural Design Institute is to pyrolysis and gasify refuse under high temperature and anoxic conditions, and produce flammable gases with CO, H2 and CH4 as the main components, which can be directly used for internal combustion engine power generation. The waste heat generated by the system can be recovered by circulating cooling system and waste heat boiler, so as to realize the cascade utilization of energy. The efficiency of the system can be increased by 95%. At the same time, the waste generated by the system can be reused as building materials. Compared with the traditional fixed gasifier, the rotary pyrolysis vaporizer adopts the rotary bed technology. The system can run continuously, control the material quantity, residence time and gasification degree in the furnace with high precision and stability, and achieve the characteristics of full utilization of waste and high power generation. At the same time, Luoyang Building Material Architectural Design and Research currently adopts the only international technology of gas purification and coke removal. Gas meets the international emission standards and the use requirements of gas power generation system, and achieves zero discharge of coke-containing wastewater.

Modular Composite Structure

Another characteristic of domestic refuse pyrolysis gasification system is modular combination structure. The unit equipment is simple, and the unit and quantity can be selected according to the treatment scale, so that the overall construction cost is low. It is more flexible and adaptable than other traditional direct incineration systems for configurations with medium capacity (e.g. less than 300 tons per day). The scale of pyrolysis gasifier is variable, it can be monomer, double or multi-body. At present, more pyrolysis gasification devices are used. The processing capacity of single standard module is 25 tons per day. According to the required processing capacity, one or more modules can be combined to achieve the best treatment and economic results. In actual operation, according to the change of garbage disposal capacity or the need of maintenance, the number of unit operation modules can be adjusted on demand, which can save operation costs.

Luoyang Building Material Architectural Design and Research Institute has reached 60 tons per day in one month according to market demand. The gasification unit is placed in a standard container of 40 GP in size, which is mobile, distributed, flexible in layout, suitable for local conditions and waste source treatment.

In addition, pyrolysis and gasification technology can be adapted to the treatment of a variety of solid wastes, that is, not only domestic waste, but also industrial and medical garbage, especially hazardous solid wastes which are not suitable for direct incineration, or which are difficult to deal with directly, including medical garbage. Especially for medical garbage and other hazardous wastes requiring treatment under fully sealed conditions, the traditional direct combustion treatment method under aerobic conditions is difficult to achieve this point. It may not only cause secondary pollution, endanger the health of specific operators, but also increase the treatment difficulty of harmful substances or gases, as well as the treatment cost. This new type of garbage management and treatment The concept of disposal (that is, all kinds of garbage can be packaged and packaged first, then pyrolysis and gasification can be carried out under a completely sealed condition) can meet the requirements of hazardous waste disposal. Even a large number of straws (wheat, maize, etc.) in rural areas can be treated by this technology.

In conclusion, we believe that the technology of waste pyrolysis and gasification is particularly suitable for the treatment of medium and small-scale solid wastes in some districts, counties and development zones of medium and small cities and big cities.