Rotary kiln lime production line is a semi-automatic lime production line composed of several separate equipment. The main power part is industrial power consumption. The operation principle belongs to batch production of chemical reaction industry. It belongs to the sunrise industry in the current building materials industry. Domestic lime kiln manufacturers have made China’s lime kiln technology rank first in the world through continuous research and development and improvement. Luoyang Building Material and Architectural Design and Research Institute is not satisfied with the existing kiln lime production technology. The Suspension Calcination lime production technology independently developed has changed the existing rotary kiln calcination technology. It not only maintains the advantages of the existing lime kiln technology, but also solves the shortcomings of the rotary kiln such as large area and large heat loss. It is one of the most advanced production technology at present. In view of two different production processes, the main equipment components are introduced respectively.

- The main components of rotary kiln lime production line are as follows:

Preheater: Preheater, as its name implies, preheat limestone raw materials. The whole wind power system of limestone kiln moves towards the kiln tail through the kiln head. The inlet and outlet of the lime kiln are at the kiln tail (kiln top), so the preheater of the lime rotary kiln will be installed at the kiln tail. The limestone will be heated to about 800 degrees Celsius through the kiln tail gas to volatilize limestone impurities and reach lime. The surface of the stone is decomposed preliminarily.

Rotary kiln: Calcination core equipment of lime kiln production line, which can heat lime to 1250 degrees Celsius so that calcium carbonate in limestone can be quickly decomposed into calcium oxide and carbon dioxide.

Cooler: Calcium oxide decomposed from the lime rotary kiln is still in a high temperature and red-hot state. The temperature of lime is reduced to no more than 60 degrees Celsius by means of cold air heat transfer. At the same time, the cold air is replaced by hot air and returned to the lime rotary kiln.

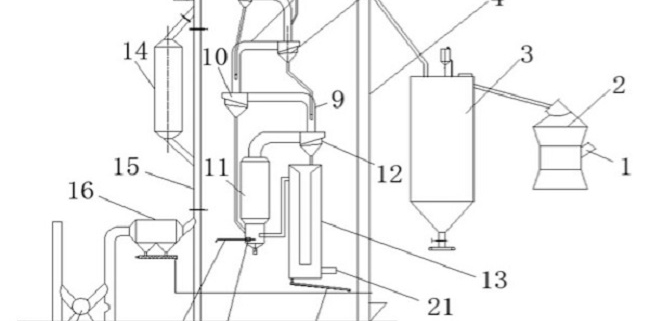

- The main components of suspension calcining lime production line are as follows:

Three-stage suspension preheating system: through the first cyclone preheater, the second preheating ascending flue, the second cyclone preheater, the third preheating ascending flue and the third cyclone preheater, the suspended powdery limestone is preheated by the exhausted hot air.

Calcinator system: CaCO_3 is decomposed into CaO and CO_2 after thorough decomposition of calcination temperature in the calciner. Activated lime after calcination enters the cyclone separator with hot air flow.

Multi-stage cyclone cooling system: the separated active lime powder flows through the pipeline into the graded cooling device, through heat exchange and cooling with the incoming air, enters the ash outlet tube, and is fed into the finished product warehouse. After preheating in this stage, the air enters the roaster for combustion.

Advanced technology is the power source to promote the development of lime industry. Luoyang Building Material and Architectural Design and Research Institute is constantly studying and innovating. The production process of suspension calcined lime will certainly bring lime production to a new stage.