Sludge is a by-product produced in the process of urban water treatment. It has the characteristics of high water content and low strength, and often contains harmful components such as pathogenic bacteria, heavy metals and toxic, harmful and difficult-to-degrade organic matter. If not properly disposed of, it will easily cause two Secondary pollution.

Traditional sludge disposal mostly adopts methods such as landfilling of sludge, land use, sludge composting, sludge incineration and ocean dumping. These methods all have certain drawbacks. Among them, ocean dumping has been strictly prohibited, and sludge landfill takes up a lot Land resources and sludge incineration tail gas treatment are difficult to control. Therefore, research on new sludge treatment and disposal technologies to achieve sludge resource utilization has attracted more and more attention.

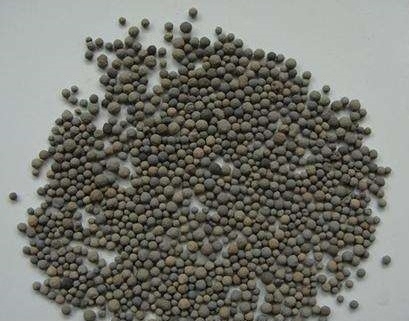

The chemical composition of the sludge is similar to the raw materials for the preparation of ceramsite, so the researchers consider using dehydrated sludge to replace clay, shale and other non-renewable resources to produce ceramsite. Ceramsite has the advantages of high strength, low density, sound insulation and noise reduction, difficult heat conduction, shrinkage resistance, rough and porous surface, and large specific surface area. It has broad application prospects in construction materials, water treatment, sound absorption materials, horticultural substrates, etc.

Ceramsite can be divided into clay ceramsite, shale ceramsite and fly ash ceramsite according to different raw materials. Clay and shale are non-renewable resources. The state has issued relevant policies to prohibit or restrict mining.

Compared with industrial sludge, water sludge and domestic sewage sludge have large output and relatively simple composition, and have become the key research object of sludge resource preparation at home and abroad. According to the preparation process, ceramsite can be divided into swelled ceramsite, sintered ceramsite and non-fired ceramsite. The sintered ceramsite has a low density, rich internal pores, and a wide range of applications. Therefore, more attention has been paid to research.