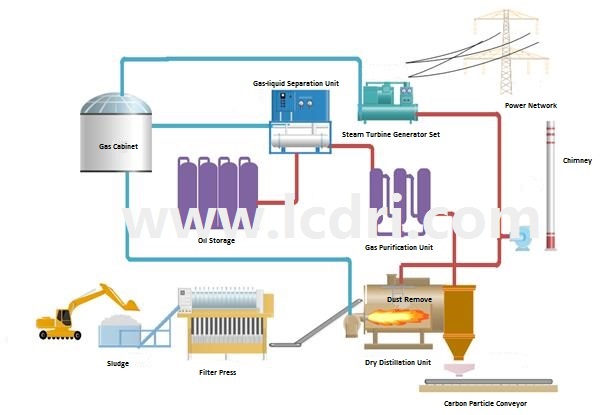

First、Process flow of sludge resource utilization

The sludge resource utilization means that the sludge undergoes a chemical reaction in a closed, anaerobic and high-temperature state, and the sludge is subjected to high-temperature pyrolysis and carbonization to produce combustible gas and bio-carbon.Thereby effectively decomposing the sludge, realizing the resource utilization, protecting the environment and achieving benefits.

1. Pressure filtration dehydration

By means of mechanical pressurization, the sludge is subjected to a pressure of 3-4Mpa to squeeze out free water between the sludge molecules. The high-efficiency filter press equipment can dehydrate 80% of municipal or industrial sludge to 50%. ;

2. Hydrothermal drying

The sludge water pyrolysis is to warm the sludge, so that a part of the cell material in the sludge is hydrolyzed, and the water in the cell is broken and separated, thereby facilitating the digestion of the subsequent sludge, and the water is hydrolyzed and dried to make the water 50% of the sludge is dried to 20% and can be sold directly as fuel;

3. Pyrolytic carbonization

Using advanced thermal machinery simulation technology and a large number of experimental analysis of sludge pyrolysis, Luoyang Building Materials Design and Research Institute developed the core unit of the process, sludge carbonization unit. The device can produce bio-carbon, activated carbon, building ceramsite, etc.; environmental protection can fully meet the requirements of Taihu Lake Basin and Beijing local environmental protection standards;

4. Calcination utilization

The bio-carbon and activated carbon produced by the carbonization process can be directly sold as products;

5. Production of building materials

Add some auxiliary materials and use brick making equipment to produce various building materials such as permeable floor tiles and wall tiles required for urban construction.

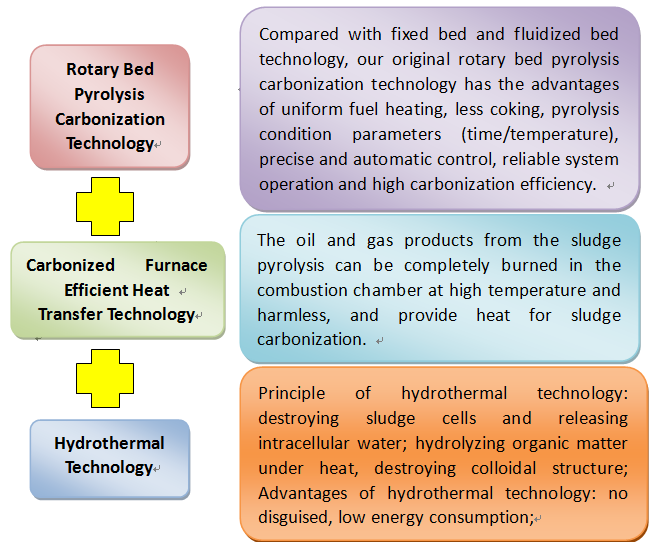

Second, the core technology of sludge resource utilization

Third, the innovation of sludge resource utilization

1. Water pyrolysis drying: using the latest low-energy water pyrolysis drying technology;

2. Multi-function: can realize different treatment requirements for sludge ceramsite + sludge carbonization + activation treatment;

3. Automation: computer control is used to realize unmanned field operation management;

4. High energy efficiency: high efficiency gas-solid heat exchange equipment with low heat consumption;

5. Reliable sealing: multiple sealing methods are adopted to ensure that the carbonization furnace is tightly sealed without leakage;

6. Emissions compliance: Clean and efficient exhaust gas treatment devices to meet the most stringent emission standards;

7. Adaptability: freely switch a variety of sludge without stopping the machine;

8. Wide adjustment range: the input amount can be changed by 0.5-3 times;

9. Low investment: equivalent to 15%-20% of the sludge-made ceramsite and sludge activated carbon production line.

In December 2018, Luoyang Building Material and Architectural Design and Research Institute independently developed and designed, providing core equipment for sludge hydrolysis and carbonization resource utilization comprehensive utilization project, which was put into operation in Huzhou City, Taihu Lake, and treated 200 tons of sludge per day. The project is a demonstration project for the “13th Five-Year” National Sewage Special Treatment Sludge Resource Utilization, which has received extensive attention from governments at all levels and provided advanced solutions for environmental management in the Taihu Basin.